Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

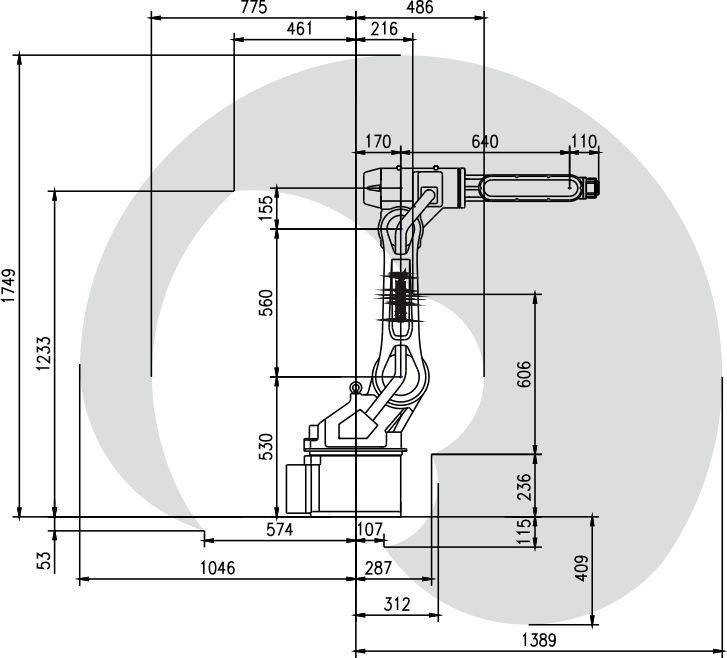

Six axis robot-RB08

Six axis robots, also known as articulated robots or serial-link robots, are a type of industrial robot that have six degrees of freedom. Application field: It is widely used in burnishing, polishing, machine loading/unloading and automatic transport on punching automation production lines.

|

6 axis |  |

±0.05mm | |

|

8KG |

|

1389mm |

Classification:

Keywords:

Six Axis Robot

Product Details

Instruction List

| Type | RB08 | |

| DOF | 6 | |

| Drive Method | AC Servo Drive | |

| Payload (kg) |

8 | |

| Repeatability (mm) |

±0.05 | |

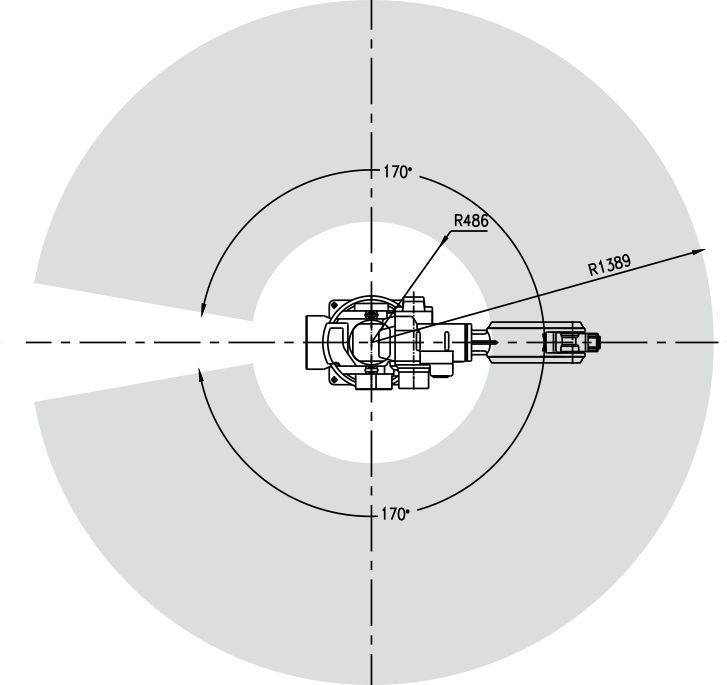

| Motion Range(°) | J1 | ±170 |

| J2 | +120~-85 | |

| J3 | +75~-155 | |

| J4 | ±180 | |

| J5 | ±135 | |

| J6 | ±360 | |

| Top Velocity(°/s) | J1 | 154 |

| J2 | 154 | |

| J3 | 154 | |

| J4 | 420 | |

| J5 | 252 | |

| J6 | 620 | |

| Allowed Top Torque (N.m) |

J4 | 14 |

| J5 | 12 | |

| J6 | 7 | |

| Motion Radius (mm) |

1389 | |

| Machine Weight (kg) |

180 | |

Six axis robots, also known as articulated robots or serial-link robots, are a type of industrial robot that have six degrees of freedom. This means they can move in six different directions: up and down, left and right, forward and backward, yaw, pitch, and roll.

The six axis robot is designed with a series of joints that allow it to move with precision and flexibility. The first joint, or base joint, allows the robot to rotate horizontally, while the second joint enables vertical movement. The remaining four joints provide the robot with additional movements, such as bending, twisting, and rotating.

Six axis robots are commonly used in manufacturing and automation applications, where they can perform a wide range of tasks with high precision and speed. They can be programmed to perform repetitive or complex tasks, such as pick-and-place, packaging, welding, painting, or assembly, with minimal human intervention.

One of the key advantages of six axis robots is their flexibility and adaptability to different work environments. The robot's arm can be extended or retracted to reach different positions, making it suitable for applications that require a large working area or a high degree of mobility. Moreover, the robot's end effector can be easily replaced or customized to accommodate different tools or objects, increasing its versatility and functionality.

Another advantage of six axis robots is their ability to perform complex and intricate motions. With six degrees of freedom, the robot can move in a variety of directions, angles, and orientations, allowing it to handle objects with different shapes and sizes. The robot's precision and repeatability also ensure consistent and accurate results, reducing errors and waste.

Additionally, the use of six axis robots can improve productivity, safety, and cost-effectiveness in industrial settings. By automating repetitive or hazardous tasks, the robots can free up human operators to focus on more skilled and value-added activities. The robots can also operate continuously without breaks, reducing downtime and increasing throughput. Moreover, the robots can perform tasks in hazardous or harsh environments, reducing the risk of human injury or exposure.

Range Of Motion

Previous page

Next page

Robot Arm

Joint Movement

Control Panel

Teach Pendant